bimetallic screw barrel

Bimetallic Screw Barrel Manufacturer

Bimetallic Screw Barrel is one of the most demanding products of Alliance technology. Our team has developed this product using the international norms. For better performance of our products we prefer to have bimetallic layer hardness between 55HRC to 72HRC.

Our team ensures the quality aspect of our product by every possible mean .

We have standard as well customized source of this product to meet the requirement of different segment of people and industry need.

Feature

- Best quality product at competitive price

- Bimetallic coating is made by 2 types

- Thickness of coating is 1.5mm

Bimetallic Screw Barrel Wholesale

We offers highest range of bimetallic screw barrel for plastics injection moulding machine, plastics extrusion machine, plastics blow moulding machine, plastics recycling machines, rubber extrusion machine, food processing machine.

Bimetallic Screws and Barrels for Alliance Technology

Wearing and corrosion are top two concerns for screw barrel people, therefore bimetallic screw barrels were born to make things better. While the cost is higher by percentage, the life time is dramatically increased by times. Therefore when the formula has additives or fillers or in not-perfect environment, bimetallic screw barrel is a better option.

Single extruder bimetal screw and barrel

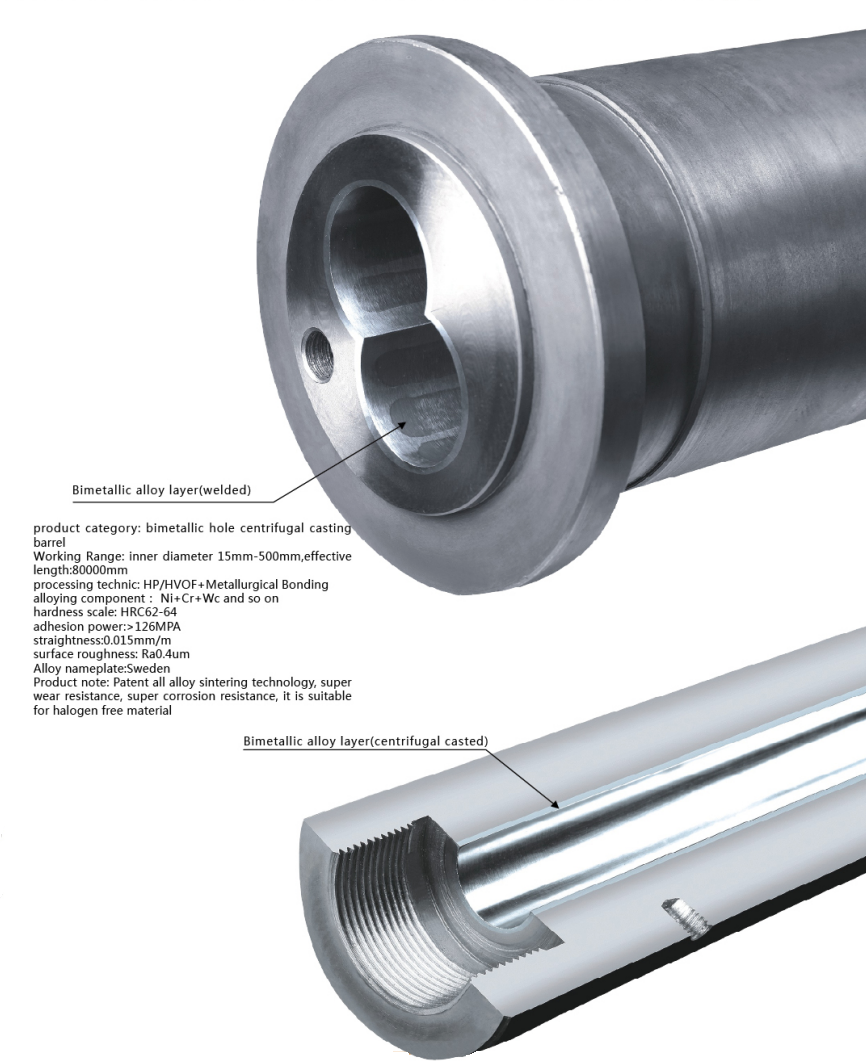

The bimetallic barrel for single screw extruder is a kind of barrel spray 2-5mm thick alloy coat on the barrel inner wall which has excellent corrosion resistance, abrasion resistance and high working temperature. Bimetal has more obvious advantages when processing special plastics to enhance the abrasion life, such as engineering plastics, fluoride plastics, PPO etc.

Twin extruder Bimetal screw and barrel

The bimetallic barrel for twin screw exruder is a kind of barrel spray a 1-3mm thick alloy coat on the barrel inner wall which has excellent corrosion resistance, abrasion resistance and high working temperature. Bimetal has more obvious advantages when processing high calcium carbonate powder PVC mixture to enhance the abrasion life.

Professional Manufacturer for Bimetallic Screw and Barrel

Alliance Technology does the bimetallic alloy coating at our own workshops, we have centrifugal casting machines for barrel alloy bimetallic treatment and Stellite machine for screw hard-facing.diameters.

Nitride and bimetallic screw barrel solution

extending the service life

Screw and barrel produced by Alliance Technology are all have quenching and nitride process. We have been dedicated ourselves to find method of anti-corrosion and anti- abrasion.

1.The steel we use to manufacture screw and barrel is 38 CrMoAl.

2.Nitride and quenching process:

- Hardness after quenching: HB280-320

- Hardness after nitride :> HV950

- Nitride depth: 0.5mm-0.8mm

3.Bimetallic screw barrel

- A.The flights of screw are grooved and bimetallic layer is coated by spray wielding method.

Nickel based alloy powder is applied. - B. SKD 61 is a kind of steel imported from Japan which is even more durable than normal bimetallic barrel. We use SKD steel to the wearing part of barrel as shown in the below picture. This high cost application is usually required in formulations with high percentage of fillers such as calcium and glass fiber or WPC.

- C.Spin casting (Applied in single barrel)

Spin casting coating method is used in single barrel as shown below.

Contact our support team now

If you have any questions, please contact us in time!

You will get feedback within 24 hours.